- Wi-Fi 6 Mesh Routers

- Heat Shrink Closures

- Cable Repair Sleeves

- Pipeline Heat Shrinkable Sleeve

- Heat Shrink Tubing Sleeves

- Aerial Closure

- Fiber Optic Splice Closures

- Fiber Distribution Cabinets&Boxe

- Optical Cross Connect Cabinet

- Fiber Optic PON PLC Splitters

- FTTH Fiber Drop Cable

- FTTH Accessories

- Broadcast

Latest news

- How to Easily Install the Channel on W

- The history of XAGA series heat shrink

- What is heat shrinkable wraparound cab

- XAGA 550 43/8-200 heat shrink copper j

- Alternative Replacement for Raychem/Co

- Replacement for TE Raychem CRSM Wrapar

Contact us

- ADD: No. 198, Industrial Avenue, Dayi County,Chengdu,Sichuan,China

- TEL: 86-28-82200303

- FAX: 86-28-82200305

- E-mail: alan.tyco@gmail.com

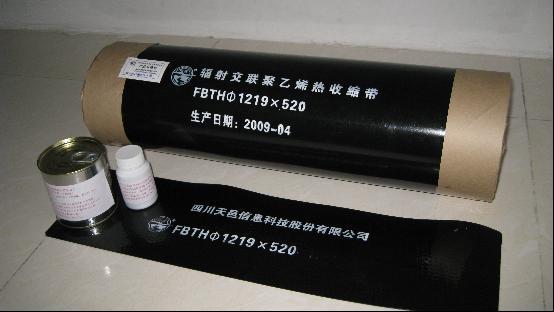

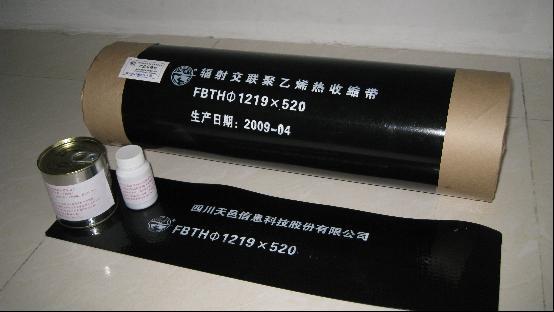

Pipeline Anti-corrosion Heat Shrink Sleeve

- Product description: Manufacturer and supplier of pipeline heat shrink sleeves provide anti-corrosion protection solutions for oil, gas and water transmission pipelines.

Product introduction

Pipeline Anti-corrosion Heat Shrink Sleeve

also called Anti corrosion joint tape for pipeline—Outer layer, joint wrap tape,heat shrinkable, HEAT SHRINKABLE TUBULAR SLEEVE etc.

Description:

Polyethlene is used the base material which is coated by the liquid butyl rubber film, both of which are pressed and compounded. It is mainly used on underground, underwater and overhead pipe lines. The function for this tape is for anticorrosion of pipe.

The Pipeline Tubular Heat Shrink Sleeve is mainly used for anticorrosion of Pipeline joints. It is a three layers ply polyethylene (PE) mechanical protection anti-corrosion self-adhesive tapes.

Features:

1. Suitable for use on pipelines operating up to 80ºC;

2. Suitable for the layer coating of 2PE,3PE,FBE and Thermal Insulation pipeline, the different jacket pipeline ,various design pressures and pipe materials corrosion protection.

Application:

The Pipeline Tubular Heat Shrink Sleeve are used as anticorrosion of oil and gas pipelines joints, both onshore and offshore pipeline; Plastic drain joint and thermal insulation weld joint and so on.

Structure:

The Pipeline Tubular Heat Shrink Sleeve has three-layered structure, the outer is Radiation Cross-linked polyethylene layer, the second layer is heat-melting adhesive, the inner is concrete coating.

Features:

1. It is featured by excellent mechanical strength, improving electrical insulation performance, good resistance to chemicals and high adhesive strength.

2. It has large shrinkage ratio. The hot melt adhesive is much mobile. Installation is fast with low preheating temperature. It is convenient to coat the Epoxy Primer.

3. Sound geological environment and weather resistance. Easy installation

4. A long-term effectiveness of the guarantee.

Ordering information:

|

Complied with AWWA C-214 Standard Normal ASTM D 1000- ASTM G8-ASTM F1249- ASTM D570- ASTM E257- ASTM D149

|

||||

| TAPE | 300.25 | 300.30 | 300.40 | 300.50 |

| Total thickness | Mils 25 | Mils 30 | Mils 40 | Mils 50 |

| Tensile | 31 lbs/in | 31 lbs/in | 41 lbs/in | 52 lbs/in |

| Elongation | 300% |

| Peel Adhesion to Primer Pipe | 230 oz/in, 18N/10mm |

| Cathodic Disbandment | 0.25 in radius 6.4 mm |

| Water Vapor Transmission Rate | 0.2g/100in2/24h,0.3mg/cm2/24h |

| Water Absorption | < 0.1 |

| Volume Resistively | 2.5 x 1012 ohm. Cm |

| Dielectric Strength | 40KV |

| Temperature Range (Normal in Ground Service) | -30 to 160°F, -34 to 71° C |

Remarks:other sizes are available according to customer’s requirements.

Pipeline Dia: 25- 1520mm

alan.tyco@gmail.com

alan.tyco@gmail.com ty.heatshrink

ty.heatshrink Alan

Alan